A burning passion for maple syrup

Maple syrup production may seem to straddle two worlds: on the one hand, tradition and the little log shack, and on the other, cutting-edge technology and large boiling centres. The two poles may appear at odds. Some believe the maple syrup industry is becoming so industrialized that it’s forgotten its roots. They fear that the flavour only buckets can provide will disappear and that family celebrations and the hours spent together in front of a wood-fired boiler—whose sounds and smells are so characteristic of the traditional process—will become relics of the past.

At the 2019 Journées acéricoles (maple syrup days) held by the MAPAQ, a fellow sugarmaker admitted his fear about this opposition between tradition and modernity: “It won’t be long before it’s the same as for milk: a truck will pick up the sap or concentrate from producers, and everything will be boiled at a big centre. And that’ll be the last of our traditional sugar shacks…” My colleague found it hard to imagine that we might only harvest sap, without boiling it, without going through the entire process that he himself has enjoyed so much since he was a kid, when he was taught maple sugaring by his father.

A world that keeps changing

Four years later, I realize—as I’m talking to people in the industry—that we’ve never sold so many small evaporators as we do now. Is this the result of the pandemic, or are people reconnecting with tradition? A combination of factors must have led us here. Micro-sugar bushes of 30, 50, or 100 taps are growing in numbers, making it a strong trend. It’s a trend that lets a growing number of people get in touch or reconnect with the tradition of maple sugaring, its gatherings, its chores, and its springtime pleasures. On the one hand, it’s true that tradition seems to be fading in the commercial production sector. On the other hand, there’s no doubt that tradition is seriously re-emerging from a recreational perspective and is showing up in family life more and more. This may not be a story that’s moving in a single direction! Despite the significant interest in small sugaring facilities, the idea of large centres expanding and increasingly taking over has stayed with me, and I’ve started thinking we might indeed lose something in the transition.

Embodying both tradition and modernity

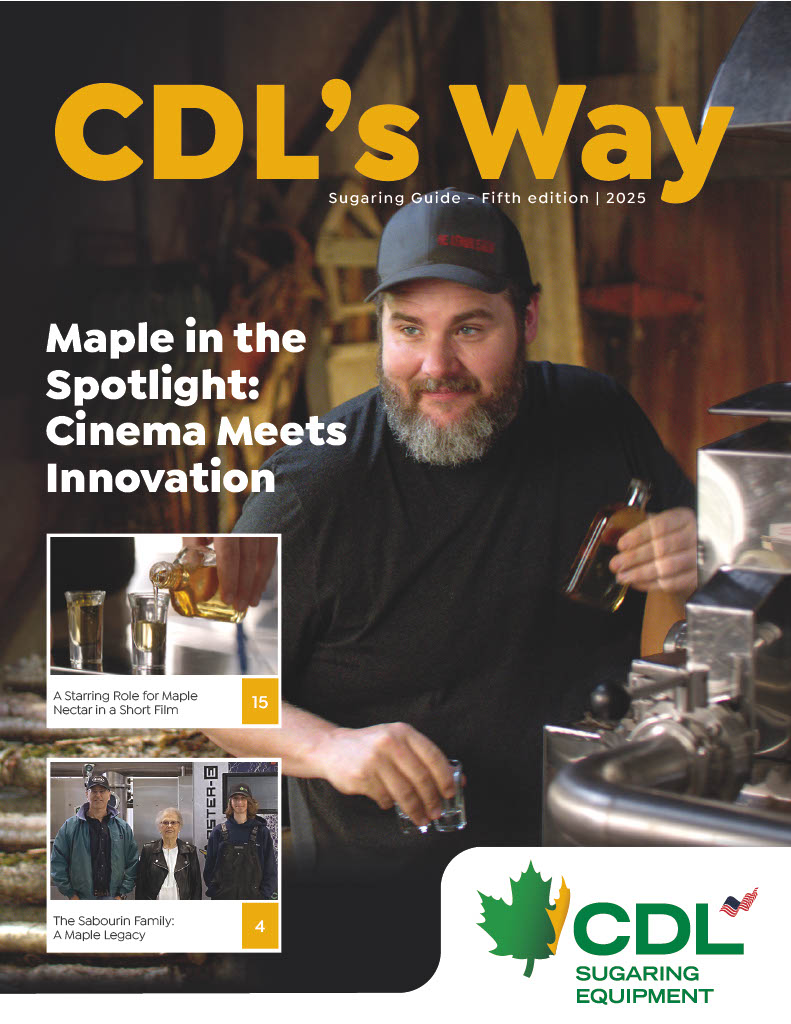

Life often gives us food for thought when we look around and pay attention. Last spring, I got the chance to help my son, a producer, make a documentary film on the passion of Jean-Marie Chabot, CDL’s patriarch. The project gave me the opportunity to visit a real boiling centre in operation—80,000 taps— and to see its atmosphere and the kind of syrup it produces.

We had an initial meeting with Jean-Marie before the sap started running. He shared his background and passions and, of course, we discussed his close ties with maple syrup production. He’s been sugaring off since he was a young boy, when he was given permission to tap a few maple trees on his way home from school. His mother would then let him cook the syrup in the kitchen. This would fill the house with maple steam, forcing everyone to throw open the windows, but would also produce the family’s supply of maple syrup for the year.

We left Mr. Chabot and promised a second shoot with his three sons, this time while his massive Master pellet evaporator would be operating. As I left, I told myself I would soon get to taste this syrup, produced with cutting-edge technology and remarkable efficiency.

Mr. Jean-Marie Chabot and his wife Mrs. Marthe Fradette

Visiting a boiling centre

One Sunday, while still in bed, I received a call from Jean-Marie: “We’re boiling, the guys are on their way—it’s now or never!” A shiver travelled through my body, as if I were a child and Santa Claus himself had just invited me to come on up and visit his toy factory! My son and I headed down the Tewkesbury mountains to Bellechasse. When we entered Mr. Chabot’s building, we discovered the same happy, excited atmosphere as in our own sugar shack, where we boil the sap of 300 maple trees. Everyone there was hard at work, in an ambiance where the focused attention required by sugaring combined with smiles and good humour.

Of course, everything was bigger: the 1,000-litre syrup containers and the steady flow of precious liquid from the evaporator and press line—everything oversized. For one of the year’s first flows, the taste of the syrup was rich, without any of the flaws typical of some early batches. “There’s a science to counteracting the woody taste of the first flows,” Mr. Chabot told me. That’s when I realized that tradition and technology need not be opposed. Our evolving maple sugaring practices are a series of choices. Science can very well be at the service of the flavours we’ve always sought in maple syrup. And while the advent of high Brix reverse osmosis systems has forced us to reflect on flavour development and cooking techniques, people often make syrup because it’s a passion. And passion is a key ingredient that elicits effort and quality alike—an ingredient that can connect us with the spirit of tradition.

A must-see documentary

Mr. Chabot’s documentary will premiere at the Open House event in St-Lazare on May 19th and 20th 2023. It will then be available on CDL’s YouTube channel. You will discover his universe, carried by the entrepreneurial culture he inherited from his mother and that he has developed in a large-scale company still rooted in the passion of maple syrup. Have a good viewing!

The three sons of Mr. Jean-Marie at the boiling centre